- Full 5 litre cylinder delivers product in one smooth stroke

- Flame proof – pneumatically operated

- Bench model

- All stainless-steel construction

- 316 stainless steel contact parts

- Honed bore with glide ring piston seal

- Self priming from floor level tank

- Variable inlet and outlet cycle speeds

- Stepless adjustable volume control

- No tools needed to strip and reassemble

- All parts marked for easy identification

- Strips and reassembles in minutes

- Fitted with positive shut-off nozzle

- Bottom up fill assembly

- Automatic cycle with on-off switch

- Efficient down to 500ml

- Fitted with filter-regulator air unit

- Simple construction allows for unskilled operation and cleaning

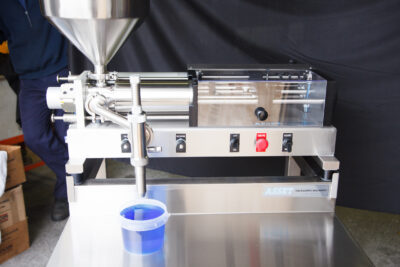

AV5-1C Single Cylinder Volumetric Filling Machine

- Bulk filling of liquids, creams, pastes and suspensions between 500ml to 5000ml

- Fast and consistent container filling, every time

- Heavy duty design to last you for decades

- Simple operation

- Easy cleaning of wet parts

- Compact construction requires minimal floor-space

Made in Australia

Machine Description

The Asset AV-5 pneumatic volumetric filling machine is a versatile and accurate liquid filling machine.

The Asset AV-5 is self-priming from any floor level tank or drum and is ideal for handling any free-flowing products such as shampoo, detergents, mayonnaise, oils or paints.

Fitted with an air-operated spool valve it can handle products with suspended solids up to 95 degrees, such as fruits and vegetable pulp mixes and sauces.

The valve is suitable for product feed from floor or elevated tanks.

| Width | 1050mm |

|---|---|

| Depth | 540mm |

| Height | 310 |

| Weight | 50kg |

| Operation Mode | Automatic, Semi-Automatic |

| Filling Nozzles | 1 |

| Minimum Container Volume | 500mL |

| Maximum Container Volume | 5000mL |

| Air Pressure Required | 600KPa |

| Air Consumption | 10CFM |

| Machine Type | Liquid Filling |

Options

- Stainless steel mobile trolley

- Adjustable height nozzle mounting

- Footswitch operation

- Programmable pneumatic cycle counter for bulk filling in multiple shots eg 10 litres or 20 litres

- Air operated spool valve fro products with suspended solids

- Automation for filling over a conveyor with container gating and no bottle/no fill switch

Some Of Our Clients

Enquire Now or Request a Quote

Registering your email address enables us to send you online communication from ASSET Packaging Machines Pty Ltd. You can unsubscribe from receiving emails at any time by using the unsubscribe link at the bottom of any emails we may send you. We guarantee 100% privacy. Your information will not be shared. You can read our full Privacy Policy here.