- Heavy duty pneumatic product cylinder drive system

- Integral 304-grade stainless steel base and cladding mounted on a stainless-steel trolley

- Bottom Up Fill Nozzle assembly

- Wet parts manufactured from 316 grade stainless steel and food grade engineering plastics

- Product piston fitted with O-ring energised Teflon/HDPE glide ring seal

- Quick connect Triclover product inlet/outlet fittings

- All pneumatic flameproof operation suitable for use with flammable products

- Individual fill speed and recharge speed controls

- Asset Rotary Product Valve system provides a positive valve seal unaffected by product supply head height

- Available in 25, 50, 125, 250, 500, 1250mL or 2000mL maximum capacity cylinder sizes

- Product cylinder and valve dismantle by hand for cleaning – no tools required

- Filling accuracy /- 0.5 or better

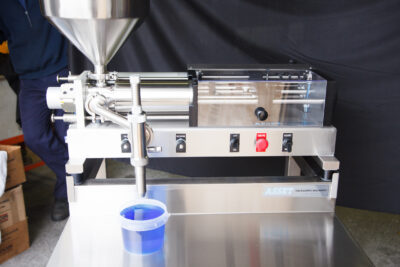

AV3-2C Twin Cylinder Volumetric Filling Machine

- Fills liquids, creams, pastes and suspensions between 5mL and 1250mL

- Twin cylinder filling for faster output

- Fast and consistent container filling, every time

- Heavy duty design to last you for decades

- Simple operation

- Easy cleaning of wet parts

Made in Australia

Machine Description

The Asset AV3-2C Twin Cylinder series of automatic filling machines offer a simple to operate heavy duty design with a proven history of reliability and ease of cleaning.

The versatility of this all pneumatic machine has now been enhanced with a completely new compact design, volume adjustment and cylinder assembly incorporating a revolutionary rotary valve system, and Australian Registered Design developed by Asset for the AV3’s big brother, the AMF Series Multi-Cylinder Filler-4C filler.

The new valve system handles products from thin liquids to creams and thick pastes, even products with soft suspended solids, a task previously requiring 2 different types of filling machine or expensive change parts. The new cylinder design enables quicker dismantling and easier more thorough cleaning of wetted parts. Various product supply methods can be used according to the nature of the product or customer preference e.g. close coupled hopper, suction hose to elevated or floor level tank, or low-pressure feed from and external pump.

Trolley mounted with lockable castors (wheels) for connection to a continuously running slat conveyor the AV3-2C comes complete with “no bottle no fill” safety device and container gating.

Ideal for use in the food industry for filling sauces (hot or cold), pate, dairy products, honey or any liquid, cream or paste type product.

The stroke adjuster and air cylinder/product cylinder drive assembly are enclosed by a safety interlocked polycarbonate cover.

| Width | 1000mm |

|---|---|

| Depth | 1400mm |

| Height | 1700mm |

| Weight | 75Kg |

| Air Pressure Required | 600KPa |

| Air Consumption | 10CFM |

| Minimum Container Volume | 5mL |

| Maximum Container Volume | 2000mL |

| Filling Nozzles | 2 |

| Operation Mode | Automatic, Semi-Automatic |

| Machine Type | Liquid Filling |

Options

- Additional sizes of interchangeable product cylinder and piston assemblies

- High temperature spool/food valves for hot filling of sauces etc.

- Twin manifold and suction hose inlet

- 2000mL capacity cylinders

- 50 litre stainless steel product hopper

- Various nozzle configurations e.g. liquid, cream, suck-back, positive shut-off, food, plug nozzle, vacuum positive shut off etc.

Some Of Our Clients

Enquire Now or Request a Quote

Registering your email address enables us to send you online communication from ASSET Packaging Machines Pty Ltd. You can unsubscribe from receiving emails at any time by using the unsubscribe link at the bottom of any emails we may send you. We guarantee 100% privacy. Your information will not be shared. You can read our full Privacy Policy here.